Lacasse: Production Shop

Thought you might be interested to know the kind of machinery we have at our disposal to make up wood mouldings, railings and stairs to meet your renovation needs. All of our machinery is relatively new. This gives us the ability to make great product, with high precision and a quality finish. Most recent acquisition is a computer controlled router (CNC) offering new advanced manufacturing capabilities, particularly for 3D carving, .. and fabricating fluted newel posts and custom size hardwood floor vents.

Weinig Profile Moulder

This machine is the Cadillac of moulders for making architectural trim…, to produce wood mouldings for the home renovation and construction market. It cuts, straightens and moulds all 4 edges in one pass.

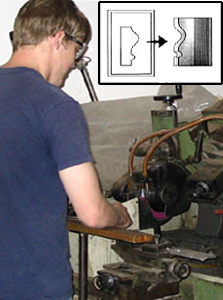

Profile Knife Grinder

You can design any moulding profile, pick your wood of choice, and we will make the knife and run the trim to match your needs – typical knife costs are $400-$600, thus viable for critical applications.

You can design any moulding profile, pick your wood of choice, and we will make the knife and run the trim to match your needs – typical knife costs are $400-$600, thus viable for critical applications.

Design Process:

- Create a computer drawing of your pattern

- Laser cut a matching plastic template

- Cut 2-4 pieces of tool steel for each pattern

- Grind the tool steel to match the template

Wide Multi-Belt Sander

A wide belt sander for the final finish on wood counters and hardwood steps up to 42″ wide. It leaves the wood perfectly flat and nicely sanded so you have little finishing work when product arrives!

A wide belt sander for the final finish on wood counters and hardwood steps up to 42″ wide. It leaves the wood perfectly flat and nicely sanded so you have little finishing work when product arrives!

It is used for final sanding of craft and exotic wood down to 1/4″ in thickness, and even thinner if jigged up appropriately.

It’s probably the oldest machine that we have in our production shop, but it still works like a charm for a full eight hour shift.

Air Assisted Clamping Facilities:

This machinery is used to produce clamp laminated panels for stair treads, mantels tops and furniture panels etc.

This machinery is used to produce clamp laminated panels for stair treads, mantels tops and furniture panels etc.