Standard Tread Finished Ends

A standard finished end on a stair tread is essential on all stairs that are open on 1 end or the other.. or both for that mater.  In other words, any time you have an open side on your wood stair treads, ie NOT hitting a wall, and the spindles are mounted on the step itself and NOT the sidewall of the steps, it is necessary (at least in my books) to finish the end in some fashion.

In other words, any time you have an open side on your wood stair treads, ie NOT hitting a wall, and the spindles are mounted on the step itself and NOT the sidewall of the steps, it is necessary (at least in my books) to finish the end in some fashion.

Just chopping it off square and letting it overhang certainly doesn’t add anything to a nice set red oak stair treads … sooo here’s an options.

A Standard Finished End tread is the most basic, the easiest to install and the least expensive option. This is what most flooring stores select for their customers. If the tread is cut a little too long or a little too short no one will ever know. It just means that the tread will overhang a little more or a little less relative to the one above or below.

So how do we do it? It’s really pretty simple.

- We make sure the wood is solid underneath on the end that is going to be exposed. Often the underside of standard treads have defects because the manufacturer assumes it is going to be installed between two walls and the back side will never be visible. In many cases this is true. But in open-sided stairs one, and sometimes both ends and part of the associated underside does show. So at Lacasse Fine Wood Products we make sure that the first two inches or so are in great shape on all of our finished-ended stair treads!

- Then we cut it perfectly square.

- With special machinery we add a completely rounded over profile across the end grain of the step. This is NOT done with a file and router as some installers insist in doing.

- Then it gets sanded smooth.

You can have all this done for less than $4.00 per step! Much less than what it would cost you in labour dollars to have your installer hack away onsite.

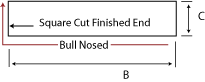

Here’s a general layout of a standard finished end tread:

In the drawing to the right, we are showing a tread with the left-hand side “finished”. We always reference the steps based on standing at the bottom of the steps and walking up…. that makes this a left-hand finished-end.

In the drawing to the right, we are showing a tread with the left-hand side “finished”. We always reference the steps based on standing at the bottom of the steps and walking up…. that makes this a left-hand finished-end.

B = the overall length of the tread from one side to the other, this number INCLUDES approximately 1-1 1/2″ to overhang on the left side of the steps

C = the standardized depth of the tread. , based on a rough step measurement of 8 ” to 10″ PLUS the 1″ needed for the front overhang to give you typically 10 1/4″ or 11 1/4″ overall depth

Bullnosing is along the front and whichever end you need (or both). As suggested earlier, you stand at the bottom of the stairs and look up.. whatever hand the open side is on is the end you order.

You can fax over or email a drawing and supply list and we’ll get right back to you with pricing. We custom make these in whatever sizes and shape you need and the wood that you desire and ship them from our factory here in Sudbury, Ontario, Canada.

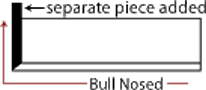

The Traditional “finished-end”

Historically a separate piece of wood has been added to the step to create a finished-end via a “mitered return”.  This adds significantly to the cost of the step, and is more inclined to damage in both shipping and living. The mitered outside corner is sharp and prone to opening especially in Northern Ontario climates with extremes of humidity, winter and summer… so rarely used these days on “solid wood” steps.

This adds significantly to the cost of the step, and is more inclined to damage in both shipping and living. The mitered outside corner is sharp and prone to opening especially in Northern Ontario climates with extremes of humidity, winter and summer… so rarely used these days on “solid wood” steps.

Mitered corners also creates more finishing challenges. A mitered return introduces wood to the end of the step in the opposite direction to the rest of the tread. If you are using a natural clear coat then no problem. But if you are staining the treads you must be particularly careful in sanding to avoid any cross-grain scratching. All scratches are highlighted ten fold, once a stain is applied to the wood.

More recently a “mitered end” has been used on imported treads, to hide the particle board core. The particle core eliminates the expansion and contraction issue, but at the cost of a step that doesn’t wear very well because of the extremely thin layer of real oak or real maple that is used on the main surface of the step. Look at the back edge of the majority of stair treads for sale in the box stores these days and you’ll see that few are real solid oak or maple.