Wood Paneling: Shiplap & V Joint

Growing concern of toxic chemicals in composite products, like MDF or bamboo, the latter being small slips of wood and lots of glue … is encouraging a comeback of solid wood paneling. Typically made from North American species that are sustainably managed. and environmentally renewable.

Lacasse has made a significant number of orders for clients that are looking for a great paintable wood (tulip poplar) that has NO sap pockets, so it doesn’t bleed out through the finish. More recently the trend has been to create a “feature wall” with something dramatic like ambrosia maple. The ambrosia beetle attacks the wood and leaves dramatic black pin holes and long brown eye shaped streaks down the wood. Just send an email or drop by for a visit and we can discuss some options

Shiplap: custom made

All shiplap is made-to-order, most often with a full 5″ wide face by 3/4″ thick. It is always better to go narrower than wider, if it is being used in an environment where humidity is not fully controlled. The wider you go, the more face nailing needed to keep wood flat.

Wood Species: Poplar for painting, ambrosia maple, pine in various grades … if we can get the wood, we can make it 🙂

V-Joint Paneling: custom made in size & wood species

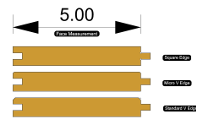

Dimensions: Lacasse makes to order, Tongue & Groove paneling …. the most common size is as the drawing suggest, a 3/4″ * 5″ face (although if used as a flooring product, standard face measurement is typically 3.25″)

V-Joint: The amount of “V” is YOUR choice. It can be made perfectly square as in the first drawing, …. A “micro V” most common in wood flooring (middle drawing) … or with a larger, more traditional “V” common in traditional Pine paneling (last drawing).